After a very, very long wait, my flares finally arrived around the same time we were working to get the engine running. Everything happened all at once, as tends to happen. Now that the car seems to run reliably and the exhaust height issue has been rectified, it was time to get the tires covered up and pick up an additional inch or 2 of fender clearance.

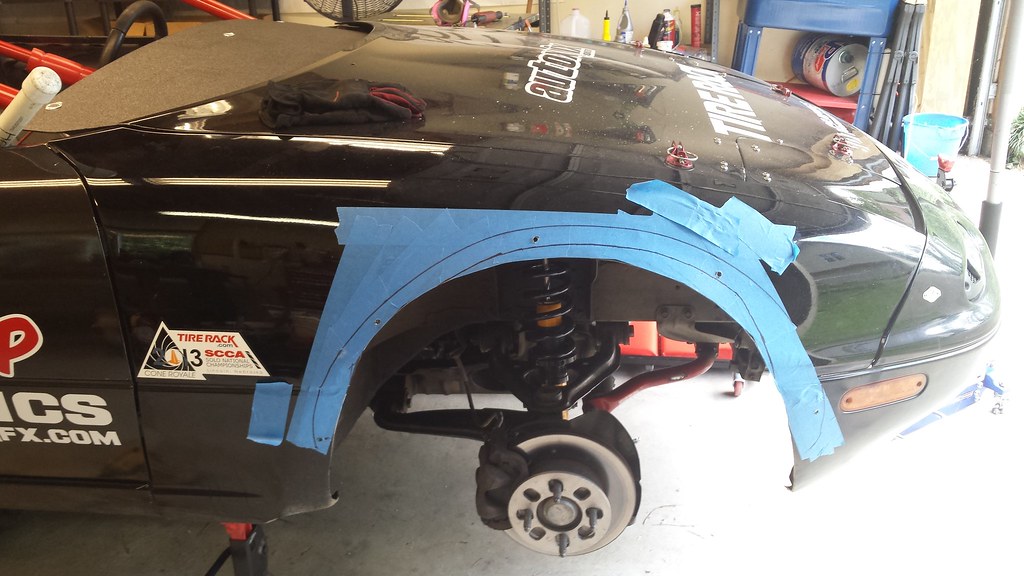

The first step is tape. Lots of tape. Less so for protecting the (awful, awful) paint, more so for having something to draw lines on.

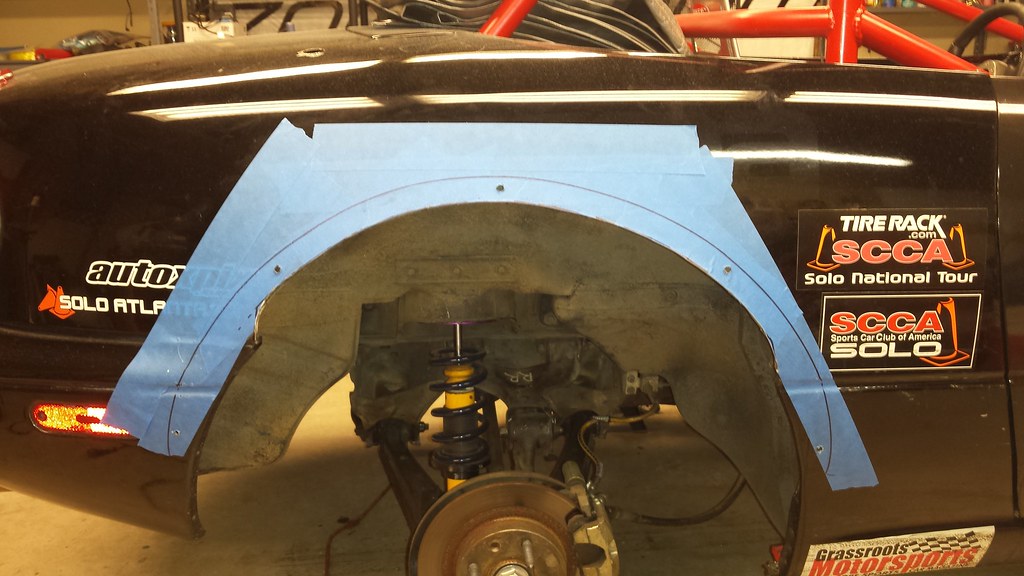

From there, with some help, we drilled 1/8″ pilot holes and used cleco clamps to mock everything up.

Once all 4 were mocked up, it was time to mark out the last final cuts, then drill out the full 1/4″ hole diameter.

Next, I had to figure out how to secure these. The fronts are pretty straightforward as you have easy access to the front and back of the fender. The rears are a bit tougher as there’s a steel inner-fender that makes it a blind install. I considered using rivets, but I really didn’t feel like having to break out a drill ever time I needed to remove a flare for some reason, so I picked up some M6x1.0 Nutserts / RivNuts. Once that decision was made, I had to figure out how to install them. You can buy tools for them, but they’re not cheap, so the next option was making a simple one.

A spare angle-grinder spanner was just the right size to give me a handle, and not be so bulky as to get in the way. I had to drill a 2nd hole because the one at the end was too large and allowed the riv-nut flange to distort (I’m so happy I tried it a few times on a piece of scrap sheet metal instead of on the car). The added advantage there was it created a bit of a flange that helped keep the riv-nut lined up flat against the panel.

Using a long M6 bolt, it’s then a matter of tightening the riv-nut against the tool, putting the assembly into a 3/8″ hole:

And then carefully tighten the bolt to collapse the knurled rivet portion. The end result came out looking like I knew what I was doing. A happy accident, I think…

I then hit the fenders with some primer (weld-thru primer in the rear, so that I can come back and weld together the inner and outer fenders), and sprayed the fenders with a few coats of plasti dip, and then 2 coats of plasti-dip glossifier to knock the flat finish off.

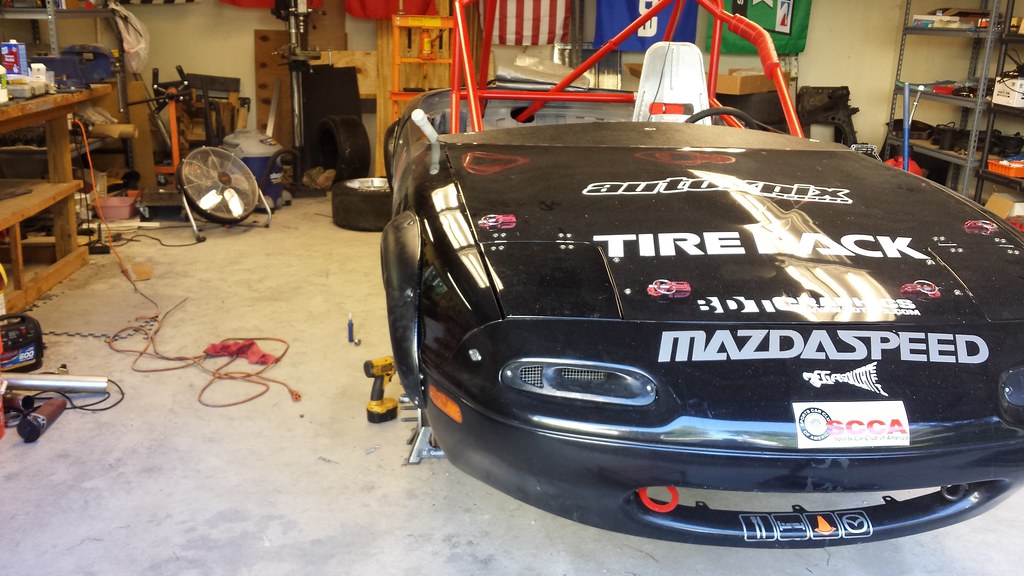

And then bolt everything up to the car. I’ve gotta say, she looks like she’s been hitting the gym. So many reps, bro!

And finally, with the wheels and tires on at ride height. BEEFCAKE! 😀