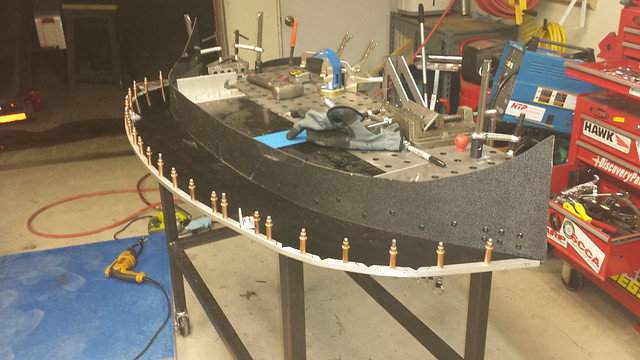

So far I’ve been loving the new splitter, however because of the nature of the DiBond, the leading edge is a bit soft and has taken a few licks. I borrowed an idea from a couple people in other classes, and put a reinforcement / trim strip along the leading edge of the splitter.

Lowes sells aluminum channel to “trim” 1/4″ ply (which happens to be the same size as the dibond my & their splitters are made of)

This will make the leading edge much less of a wear surface. Bending and pie-cutting this stuff in a way that doesn’t cause stress fractures, and slotting it to clear the mounts is a royal pain, but it will add a ton of longevity.

I reinforced both the front and rear edges. The front is to protect the leading edge of the Dibond. The spar across the rear is to add a little more rigidity along the ‘long’ side of the splitter.

The fact that it looks a little Mad Max-ish doesn’t hurt either 😀